Turtle Sense

- Using high tech sensors and cell phone networks to protect sea turtle hatchlings

Background

Sea turtles have existed for 100 million years, but in the last century, the impacts of man through accidental capture in fishing nets, habitat destruction, pollution, and plastics in the ocean have significantly reduced populations by as much as 95%. Six of the seven species nest in the warmer beaches of the US, and all of these are protected by the Endangered Species Act of 1973. Although volunteer groups and park personnel can identify egg-laying sites almost immediately, the hatching date (when they emerge onto the beach) cannot be predicted—it will happen sometime in a six-week period beginning 50 days after the eggs are laid. All 100 to 150 of the sea turtle hatchlings in a nest usually appear simultaneously (mostly at night) on some unpredictable date during that six-week period. The hatchlings “boil” out of the sand and begin a dash to the ocean, one of the most touching sights in nature.

Beginning at 50 days after the eggs are laid, the National Park Service (NPS) at the Cape Hatteras National Seashore fences off a lane from the nest to the ocean and forbids other access to that lane until either the hatchlings appear or the 100 days has elapsed. This long protection period creates conflicts with other uses for beach access, such as fishing and vehicular movement for recreation and safety. Conflicts are inevitable, often leading to lawsuits.

Project Objective

The goal of the project is to develop simple, inexpensive technology for determining when a "boil" will occur with as much accuracy and reliability as possible. The current design employs a sensor that measures egg motion either as the embryos agitate in the egg or as the sea turtle hatchlings begin to pip out of the eggs or both. The results, perhaps including modeling, will hopefully be able to predict hatching dates (arrival on the beach) to a reliable one-to-three-day window, a significant improvement over the current six-week window. Developing a reliable technology for predicting hatching will allow the NPS to create a new protocol for protecting the nests, thus freeing up access to the beaches for a significantly longer time.

There are several possible beneficial side effects of the technology:

- The technology can be used to help develop ecotourism around the hatching of sea turtles. Once people (especially young people) experience the hatching of these creatures, they may be much more likely to think positively about the welfare of sea turtles in the future.

- If local people can develop an income around this ecotourism activity, they may be less averse to the obstructions to beach vehicles and foot traffic.

- The technology might be useful for scientists studying sea turtles and might be adaptable for the study of other egg-laying species.

All the designs and software code will be published on this website and will be available for use worldwide. All data created by the system will be made available to researchers worldwide.

History

The device began with an idea from Eric Kaplan, founder of a company that develops Bluetooth wireless technology test equipment. Kaplan sold his company to his employees and later founded the Hatteras Island Ocean Center (www.hioceancenter.org), a nonprofit, 501(c)(3) ecology education center on Hatteras Island in North Carolina. Kaplan saw the need for this technology and approached his childhood friend Tom Zimmerman, an IBM Research–Almaden (San Jose, CA) electrical engineer for assistance. Zimmerman designed the sensor package in 2013 as a public service commitment from IBM. Tom recruited his college buddy, Samuel Wantman a retired software designer, and they worked on developing the first phase of the design with support from IBM and from the National Park Service. Britta Muiznieks, a biologist with the NPS has been coordinating the Park's involvement. The first phase of the project was a very quick and inexpensive hack of cell phones with a simple custom circuit board to test the viability of the project. The devices were tried in a few nests in 2013, but unfortunately it was too late in the season to get any data from viable nests. Even so, there was enough learned to make everyone involved in the project believe that there was the potential to make the technology work.

Wantman took over management of the project in 2014, as Zimmerman had to return to other commitments at IBM. Additional volunteers were recruited, including David Hermeyer a retired electrical engineer and Charles Wade a retired IBM Research manager. Phase Two of the project involves developing a more robust custom sensor embedded in a plastic sphere the same size and shape as a turtle egg, with industry standard technology for transmitting data over cell phone networks. Installation has begun on multiple sensors that the NPS is funding for field testing in 2014. The project inspired Samuel Wantman to start Nerdswithoutborders.net to help organize the project, recruit volunteers, and inspire other projects. All of the Turtle Sense project members, with the exception of the NPS employees, donate their time. The Hatteras Island Ocean Center is the sponsoring non-profit institution that administers receipt and disbursement of funds for materials and other expenses.

Phase One (2013 Turtle Season)

Phase One was a proof-of-concept field test undertaken during the 2013 turtle season. A motion-and-temperature sensor (Analog Devices ADLX362, 3-Axil, Digital Output MEMS accelerometer), soldered to a Sparkfun “breakout board,” was soldered to a CAT5 cable. The board was sealed in a Ping-Pong ball by filling it with “aquarium safe” silicone caulk. The Ping-Pong ball, about the size and shape of the sea turtle eggs, was placed in the sea turtle nest by National Park Service (NPS) rangers. The other end of the cable attached to the "egg" assembly was electrically connected to a hacked cell phone that was programmed with a very small, low-powered TI MSP430 microprocessor. The phone sent out text messages with the motion and temperature data every two hours. The cell phone was protected from the elements by a communications tower made from 4" PVC pipe and pipe fittings.

Turtle eggshells are thick and leathery, so the hatchlings need considerable effort to emerge from the egg. After leaving the egg, the hatchlings remain in the nest for two-to-four days before exiting (usually) as a group onto the beach. All the resulting motions should activate the accelerometer sensor and thus provide data to the phone network. Though the first device had its problems, field tests done at Hatteras in October 2013 were positive. The signal from the sensor close to a single hatchling was eight times larger than the background signal, giving hope for more extensive tests planned for 2014.

Phase Two Description

See also: Turtle Sense/Phase Two

Planning for Phase Two began during the implementation of Phase One. Samuel Wantman and David Hermeyer began working on the design for a more robust solution in the Fall of 2013. Units were installed by the NPS starting in June of 2014. About a dozen nests were monitored and predictions were made as to when the hatchlings would emerge.

Several problems were identified during Phase One that we tried to address in Phase Two:

- The sensors had reliability problems communicating with the cell phones because of the long distance between the sensor and the microprocessor in the communications unit. This is being addressed in two ways. The sensor was mounted on a very small (1 inch by 1 inch) circuit board inside the "egg" that goes in the nest. The board also contains a microprocessor and a RS485 transceiver that allows reliable communication over very long cable lengths.

- The cell phone, having been designed with a human interface, was often unpredictable. Occasionally messages would pop up prompting a human reply (like a notification that the phone was charging). This made programming the device difficult because of all of the possible messages and the timing of their appearance are not predictable. At one point, the devices stopped working because the cellular service provider required all its users to upload new operating software. An appropriate user response was not possible in field-installed pre-programmed units. Because of this problem, we adopted industry standard M2M (Machine to Machine) methods of sending data over a cellular network.

- Text messages and disposable cell phones were not a cost-effective way to send large amounts of data. Phase Two uses FTP protocols with devices and data plans that have much less expensive data charges.

- Hacked cell phones would be difficult to mass produce, so the new design uses off-the-shelf, plug-in cell phone boards and custom circuitry that can be mass produced.

- Phase One used single-use D cell alkaline batteries. Phase Two uses rechargeable NiMH AA batteries and achieves longer battery life, as the package is carefully designed for low energy needs.

- Most of the turtle-specific calculations are now done in the microprocessor embedded with the sensor in the "egg." The communication system is designed so that it can be modified for other sensors.

- The silicone filling the ping-pong balls that housed the sensors in Phase One never cured. For Phase Two, we made a casting of a ping-pong ball (which is the same size and shape as a turtle egg), and used it to cast solid polyurethane "eggs" around the sensor circuit boards. The polyurethane is fully set in less than a day, does not out-gas, and is very hard and durable.

Phase Two results

2014 season

- For more detail, see:

2015 season

We successfully monitored nests at the Cape Hatteras National Seashore.

For graphs of the nests that were monitored see: Turtle Sense / 2015 Season Results

Phase Three Description

See also: Turtle Sense/Phase Three

Phase Three Goals

Work on phase three began after the end of the 2014 season. The goals of Phase Three are:

- To refine our hardware so that it is easier and cheaper to manufacture, more reliable, and easier to maintain.

- Extend the firmware so that it has better error handling, can be updated in the field, and offers more features and usable data.

- Create a working, somewhat complete website which does the following: automates the process of predicting hatching, reports predation events and over-washes; generates alerts for users; centralizes necessary data entry; and, allows open access of data for researchers and wildlife managers.

- Test the equipment and features in several different environments.

- Attend conferences to publicize our work and find additional organizations to team up with, and find additional volunteers to assist the project.

- Create a plan to get the technology included in protocols that are acceptable to the US Fish and Wildlife service.

Most of the technical work to make this happen will be done during 2015. The phase two equipment will be used until the phase three equipment is ready.

Phase Three Progress

Work is underway modifying the Turtle Sense hardware and software.

Hardware

- A moisture detector is being added to the smart sensor "egg".

- The power supply of the unit is changing from 8 AA rechargeable batteries that just last for a season to a solar cell that will charge 3 AAA batteries. Preliminary tests indicate that this will be cheaper to produce, and last for many years -- as long as the life of the batteries -- before needing servicing. Initial testing is very positive. There is enough light on a very overcast day to keep the units running, and even without any light the units will continue running for several weeks.

- Connections between the comm unit and the sensors will be made with coax cable. This will allow the connections to be modified and repaired in the field, greatly reduce the expense and time involved in creating the devices, and allow multiple sensors to be connected to the same comm unit. Power and two way communication will all use the same wire.

- Expansion ports will be added for USB/SD support, Bluetooth and other wireless capabilities, and auxiliary connections for controlling and interfacing with other field equipment.

- Since the batteries will not need annual servicing, the comm units will only have one sealed chamber instead of two. This will simplify the construction and installation of the devices

- Upgraded microprocessors will expand available memory from 16K to 64K while lowering power usage.

Software

- Expanded memory provides space for better error handling, increased data storage, and user code.

- A protocol will be developed for interfacing with multiple sensors

- Tools and libraries will be help others customize the hardware and software for other applications

Data

- See also: Turtle Sense raw data

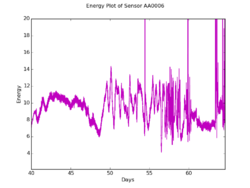

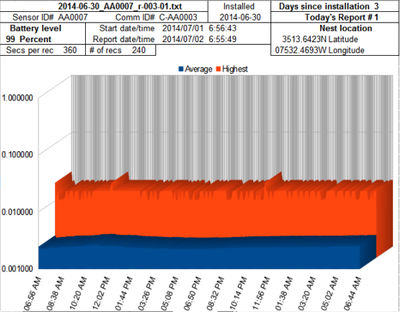

The Turtle Sense units constantly monitor and analyze motion to create a profile of its magnitude over time. The motion detector measures the change in acceleration (or "jolt") multiple times per second. The magnitude is squared and summed. After six minutes, the results are stored in a record along with a temperature and orientation reading, and the process starts over. The sum that results is roughly the total energy recorded in the nest during the period. This process allows us to compress several thousand readings into approximately 32 bytes of information. We lose but we suspect that those details are not important. The 240 records created each day give us a very good idea of what is happening in the nest. Once 40 days have passed, we restart the process of summing every minute to get more detailed data.

There has been some research that indicates that before emerging from the nest in a "boil," turtles that have hatched congregate underground near the top of the nest. It is thought that this motion stimulates the hatching of the turtles that haven't yet emerged. Our sensors, situated at the top of the nest, were able to record some noticeable disturbances several days before the turtles boil. We were able to see these disturbances in the data in almost all of the nests that we monitored in the 2014 season and were able to predict the date of the boil within a window of a few days.

Predictions from the data in 2014 were made by human observation of graphed data. We will be generating algorithms to predict hatching from our data and refining them to come up with a reliable automated process for predicting hatching a few days in advance.

Funding and Impact

The National Park Service has been funding the project since it began. Labor is being provided by NerdsWithoutBorder.net volunteers. Additional support has come from:

- IBM -- grants

- Janus Remote Communications -- a generous discount on their M2M plug-in boards

- Screaming Circuits -- a donation of the labor toward the production of circuit prototypes

- Telit -- publicity

- Frontline Test Equipment, Inc. -- a donation of communications testing equipment

- Hunan Corun New Energy Co.,LTD -- a donation of rechargeable NiMH batteries

We are seeking funding and volunteers to expand the program.

Success in this project would provide widespread, international advantages. As noted above, the stress could be lessened between the protection agencies and the fishing industry, recreational users, and tourism advocates, all of whom desire more beach access. More effective international protection will be available, since the protection resources can be concentrated close to the hatch date instead of being stretched over six weeks. With a tighter hatching schedule, the public would have the opportunity to observe the hatchlings heading for the sea, an observation available only randomly now. This would improve the public support of the turtles. NPS will use the hatch dates in on-site announcements and information centers, and the Hatteras Island Ocean Center will disseminate the information in their programs. Much of the research on sea turtle eggs and hatchlings in the world could benefit from more accurate predictions of the hatch date. For example, studies that require capturing hatchlings for research could be done with much greater efficiency. Also, the sensor/cell network could be adapted for measurements of other species, including birds. Given its modest cost and energy efficiency (long battery life), it may have other uses in environmental studies. All the design information will be available to the public on the wiki http://nerdswithoutborders.net. If the project is successful equipment will be made available at cost or perhaps below cost if sponsors come forward.

Press

Radio

- NPR's Here & Now:

- Article at PilotOnline.com (Virginia-Pilot) (August 2014)

- Article in Island Free Press(Aug 2014)

- Article in Outer Banks Voice (August 2013)

- Another mention at the Outer Banks Voice

Web

- Engadget.com

- Tech-talk at IEEE Spectrum

- Article at PsychologyToday.com

- Blog at hackaday.com

- Article at nextgov.com (August 2014)

- Telit press release in the Wall Street Journal (May 2014)

- Blog at iotworld.com

Links

- Hatteras Island Ocean Center website

- Entry for the Hackaday Prize at hackaday.io

- Video about the project at YouTube

- Turtle Sense/People -- People involved in this project.

Contact us

If you would like to help with this project, make suggestions, or offer a critique, please email: admin@nerdswithoutborders.net.

Thank You!